Home > SMT Inspection machine

Online Automated AOI Machine Z588

AOI Specification:

Online Automated AOI Machine Z588

Flexible / versatile AOI

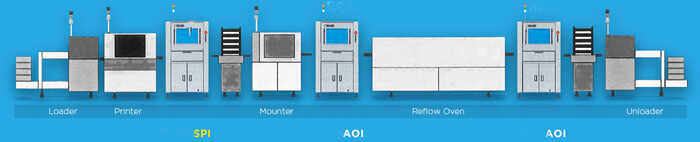

Different models are suitable for the production of multiple quality control positions in the line, including 2D solder paste quality inspection after solder paste printing, component measurement before reflow soldering, PCBA process quality inspection after reflow soldering, and hand-insertion wave soldering inspection

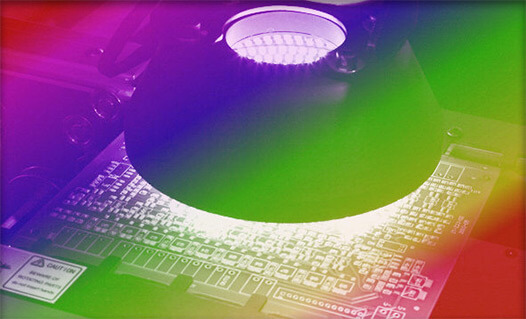

New light source design

The multi-angle multi-angle light source design scheme is used to sample the detailed features of the detected object by different angles of illumination, and the assembly and welding information of the component are accurately obtained, and the defect is effectively eliminated.

Multi-algorithm free combination

Z series software can use multiple detection algorithms in the single detection frame according to the detection needs, avoiding repeated frame pull, improving program design efficiency and bad detection rate.

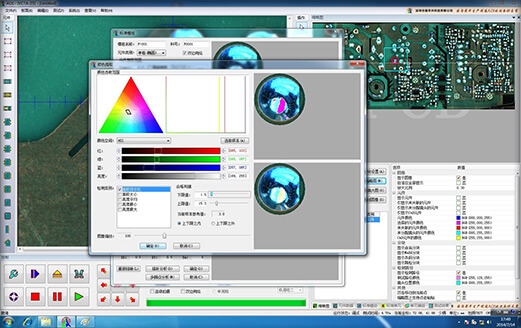

Multi-function color extraction

Z series software can effectively detect the defects of surface mount, red glue process and wave soldering process to prevent leakage of defective products.

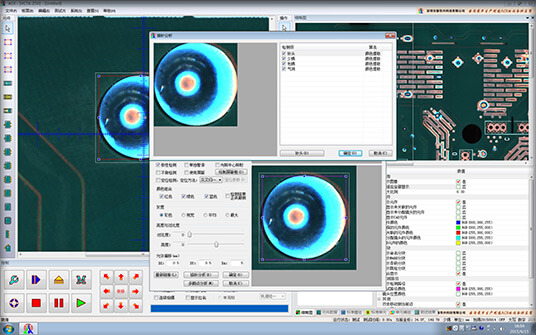

BGA detection function

It is used to detect whether the BGA solder ball is less tin, tin, ball, and tin before the patch. In addition, it can also be used for PCB solder paste printing in the BGA area, such as less tin, missed printingn

Z series software can effectively detect the defects of surface mount, red glue process and wave soldering process to prevent leakage of defective products.

Inspection System & Optical System

|

Inspection Object |

Skew / Tombstone / Wrong part / Missing / Overturning / Damaged / |

|

Inspection Component |

01005 chip , IC pitch 0.3mm, wave soldering point |

|

Inspection Method |

Color image comparison, OCR, IC Short Analysis, Graphics Similarities Analysis, Color Analysis, Gray Analysis |

|

Camera |

Color CCD (2M) , Resolution 15um, FOV 24*18mm, Speed :2000 mm2/s |

|

Light Source |

RGB cascade multi-angle LED combination lighting, high brightness, 2M pixels tele-centric lens, DOV:8mm |

Software & Computer

|

Inspection capability |

120 points/sec ; programming time : 1-1.5 hr/1000 components, NG inspection rate >99% |

|

Mark Recognition |

2 points, support multi-board multi-mark points, support bad mark ; Process speed 0.5sec/pcs |

|

Computer |

Dual core 2.7G, DDR II 2.0G, 500G hard disk, 22" wide screen LCD |

Mechanical System

|

PCB Thickness |

0.3 - 5.0 (PCB curvature?5mm) |

|

PCB Height |

Top: 30mm, Bottom 35mm (can be customized) |

|

Driving Method |

AC Servo Motor + ball screw rod + linear guide rail |

|

Motion Speed |

Max 700mm/s |

|

PCB Size 330×400mm |

, Auto-width adjustment |

|

Conveyor Height |

900± 20mm |

|

Power |

220V/50Hz, 650W,UPS 1000 VA uninterruptible power supply |

|

Compressed Air |

Max 0.3MPa |

|

Dimension |

1000mm×960mm×1600mm (alarm lamp height not included) ; alarm lamp height: 550mm |

|

Weight |

670kg |

Keywords:

SMT AOI Machine, Offline AOI Machine, Inline AOI Machine, SMT X Ray Machine, SMT SPI Machine, 3D SPI Machine, 3D AOI Machine.

Contact: Mr Tommy

Phone: +86 13691605420

Tel: +86 -755-85225569

Email: tommy@flason-smt.com

Add: 94#,Guangtian Road,Songgang Street,Bao an District Shenzhen China