Home > Siemens Pick and Place Machine

Siemens SIPLACE X3S+SX2 (+WPC) Pick and place Machine

Description:

Siemens SIPLACE X3S+SX2 (+WPC) Pick and place Machine

The latest generation of Siemens placement machine SIPLACE XS Series,

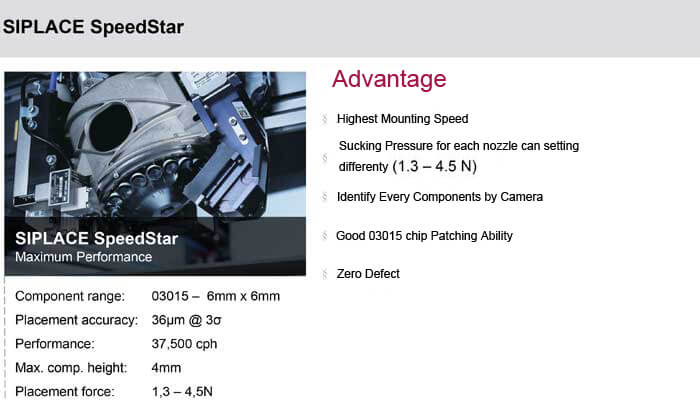

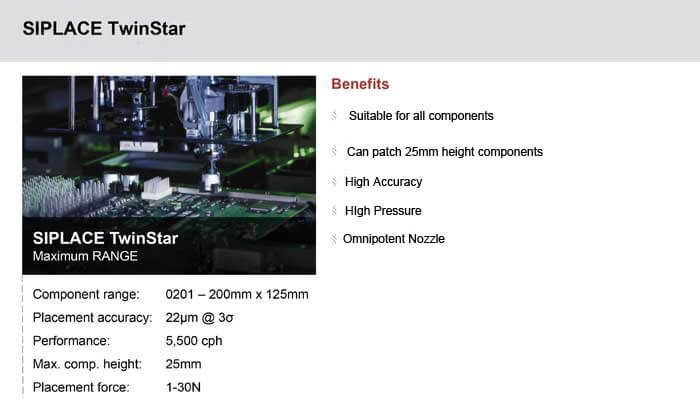

High-speed and high-precision mounting 03015 components, designed for zero yield, flexible single and double rail, advanced vision system, true intelligent feeding, adapt to all materials, can be replaced with cantilever,

Meet customers' high volume and high quality production.

Recommended SIPLACE XS Series wiring:

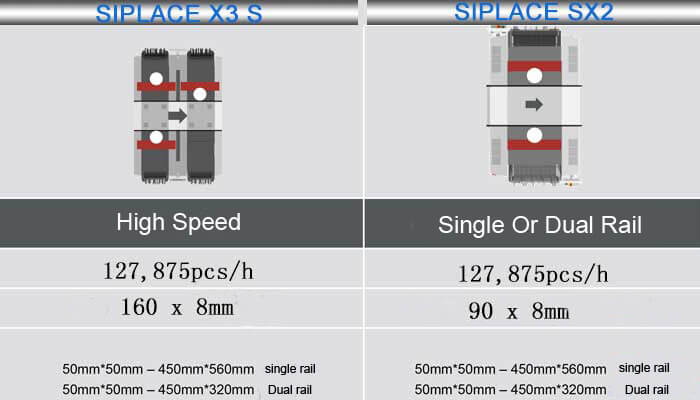

Production line configuration: SIPLACE X3S+SX2 (+WPC)

Siemens SMT shooter: D4, D2, D1, S20 25 27 50 60, F3, F4, F5

Theoretical capacity: 158,875 components / hour

Mounting accuracy: 22 microns @3sigma

Feeder capacity: 250 8mm + 28 layer automatic Ic feeder

Mounting component range: 03015 ~ 200 x 125mm

Machine configuration:

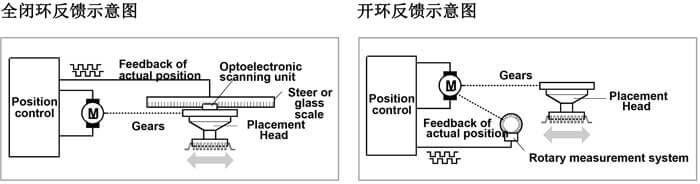

SIPLACE uses a fully closed loop positioning system

High precision grating scale with 1 micron accuracy

Real-time feedback of the X/Y/Z position of the head movement

The full closed loop feedback system is guaranteed with high precision and high repeatability!

Real-time detection of components during pick and place

Laser detection

Before picking up components / after sucking / before mounting / after mounting

Is the laser detection component normal?

The component supply batch changes, causing component height changes. It can also be adjusted automatically by the component sensor.

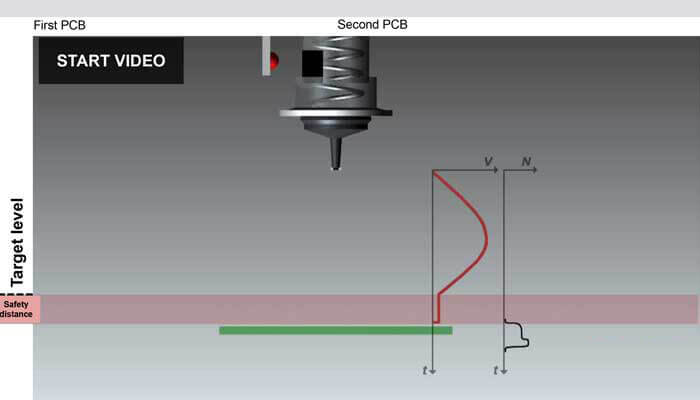

Mounting pressure automatic sensing (normal PCB)

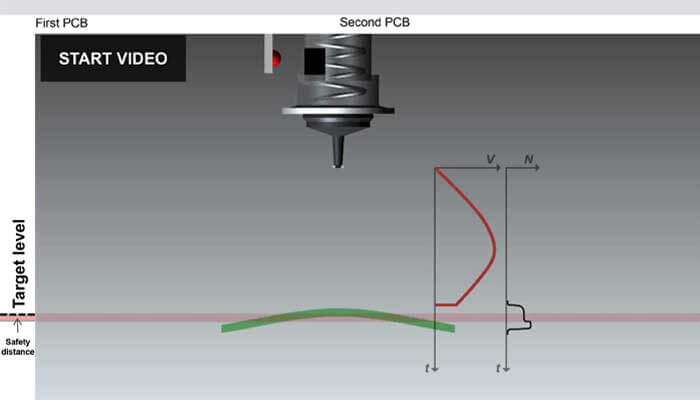

Mounting pressure automatic sensing (PCB up)

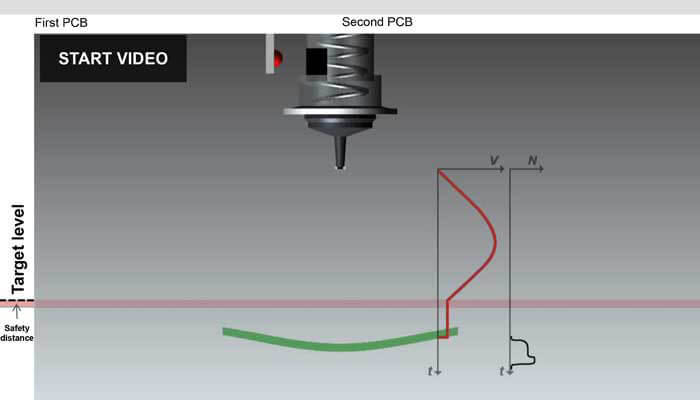

Mounting pressure automatic sensing (PCB down)

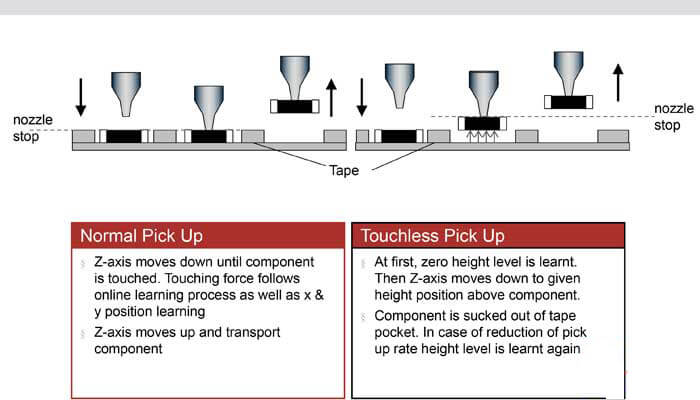

Non-contact suction for components 0201 and smaller

SIPLACE digital camera

Real-time detection of component defects before placement

Improve placement reliability

Automatic correction even if the polarity is wrong

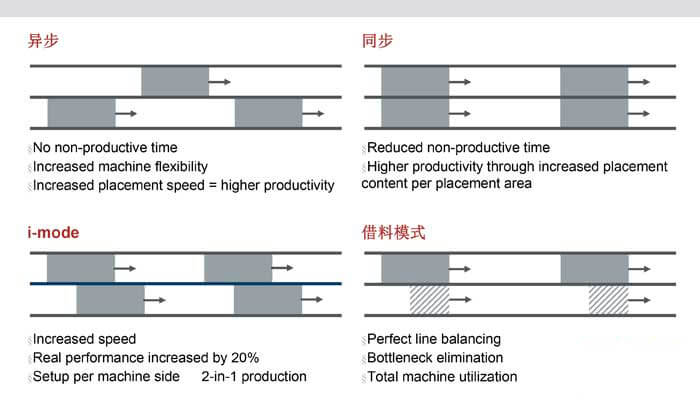

SIPLACE flexible dual-track production mode

SIPLACE X-Feeders - wireless, smart feeder

Benefits to customers:

LED display

Self-correcting, no calibration required

Use all steps

Wireless, intelligent

Support random insertion

The step can be transferred to the Feeder after being set by the computer.

Tape feeder width: 4mm – 104mm

Tape reel diameter: 178mm – 483mm (7"-19")

Changeover time: 8 seconds

SIPLACE WPC-automatic IC feeder, uninterrupted loading

Storage capacity: 28 WTC’s

Capacity per WTC: 10 Trays

Max. comp. height: 40mm

SIPLACE service system

First, 24-hour hotline service and arrive at the customer site within the promised time

Second, Siemens original technical support, complete internal procedures

Third, ample spare parts library, updated regularly according to customer needs

Fourth, standard and professional training

5. Strong service and support

Keywords:

JUKI RS-1R pick and place machine, JUKI RX-7R pick and place machine, Hanwha SM481 Plus Pick and Place Machine, Hanwha Decan S2 Pick and Place Machine, SMT pick and place machine, JUKI Pick and place Machine, Samsung Pick and Place Machine, Yamaha Pick and Place Machine, Panasonic Pick and Place Machine, FUJI Pick and Place Machine, Siemens Pick and Place Machine.

Contact: Mr Tommy

Phone: +86 13691605420

Tel: +86 -755-85225569

Email: tommy@flason-smt.com

Add: 94#,Guangtian Road,Songgang Street,Bao an District Shenzhen China