Home > Panasonic Pick and Place Machine

Panasonic BM Series Pick and Place Machine

Description:

Panasonic BM Series Pick and Place Machine

Panasonic BM Series PCB Placement Equipment

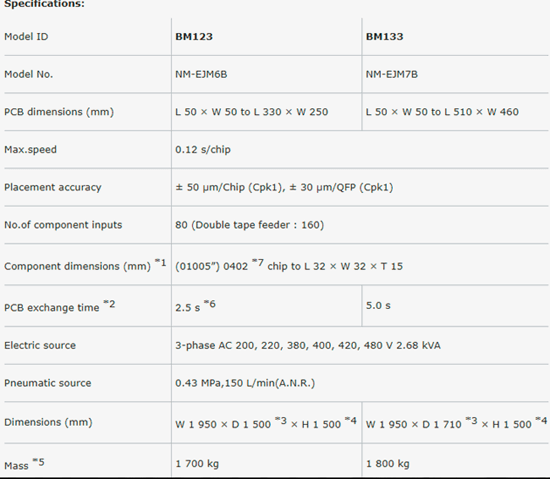

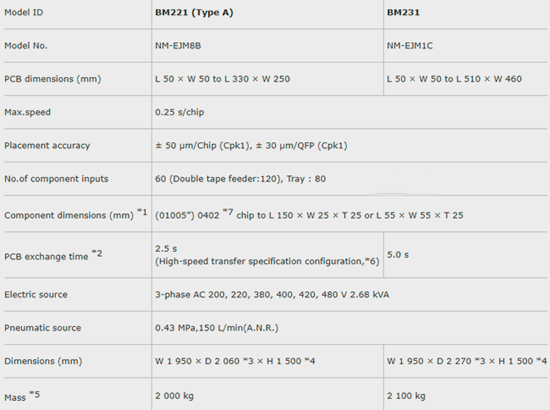

1:Varies depending on selectable Specifications.

2:It varies depending on the specification of PCBs.

3:Excluding batch exchange cart and tape feeder.

4:Excluding recognition monitor and signal tower.

5:Fixed component supply unit specification

including a feeder cart : BM123 : 2 100 kg, BM133 : 2 200 kg, BM221 : 2 200 kg, BM231 : 2 300 kg

A wide range of component, quick changeover capabilities

Panasonic BM Series PCB Placement Equipment

Ensures continuous productivity by placing components from (01005”) 0402* to L 55 mm × W 55 mm or L 150 mm × W 25 mm components on tape, reel and tray.

The BM221 & 231 offer productivity with up to 120 tape and 80 tray (JEDEC standard) inputs.

Fast, accurate placement

The 8-nozzle vertical drive provides batch recognition and batch pick-up for components in variable heights (It differs depending on the condition).

A variation of available options for the supply unit [BM221]

2D and 3D sensors are used to accurately place components ranging from microchips to L 55 mm x W 55 mm x T 25 mm, QFPs, BGAs and CSPs.

Chip thickness measuring sensor (optional)

The chip thickness senser measures the thickness of components to improve placement quality.

Direct tray support function

Keywords:

JUKI RS-1R pick and place machine, JUKI RX-7R pick and place machine, Hanwha SM481 Plus Pick and Place Machine, Hanwha Decan S2 Pick and Place Machine, SMT pick and place machine, JUKI Pick and place Machine, Samsung Pick and Place Machine, Yamaha Pick and Place Machine, Panasonic Pick and Place Machine, FUJI Pick and Place Machine, Siemens Pick and Place Machine.

Contact: Mr Tommy

Phone: +86 13691605420

Tel: +86 -755-85225569

Email: tommy@flason-smt.com

Add: 94#,Guangtian Road,Songgang Street,Bao an District Shenzhen China