Home > SMT Stencil Printer

Full Automatic Inline SMT Stencil printer GD450+

Products description

Full Automatic Inline SMT Stencil printer GD450+

GD450+™ Specificataion

PCB Parameter

Max PCB size (X x Y)

450mm x 350mm

Min PCB size (Y x X)

50mm x 50mm

PCB Thickness

0.4mm~14mm

Warpage

Max. PCB Diagonal 1%

Max PCB weight

10Kg

PCB margin gap

3 mm(conveyor belt PCB/frame touching width)

Max bottom gap

15mm

Conveyor Speed

1500mm/s(Max)

Converyor height

900±40mm

Conveyor direction

L – R、R – L、L – L、R – R

Conveyor method

Single rail

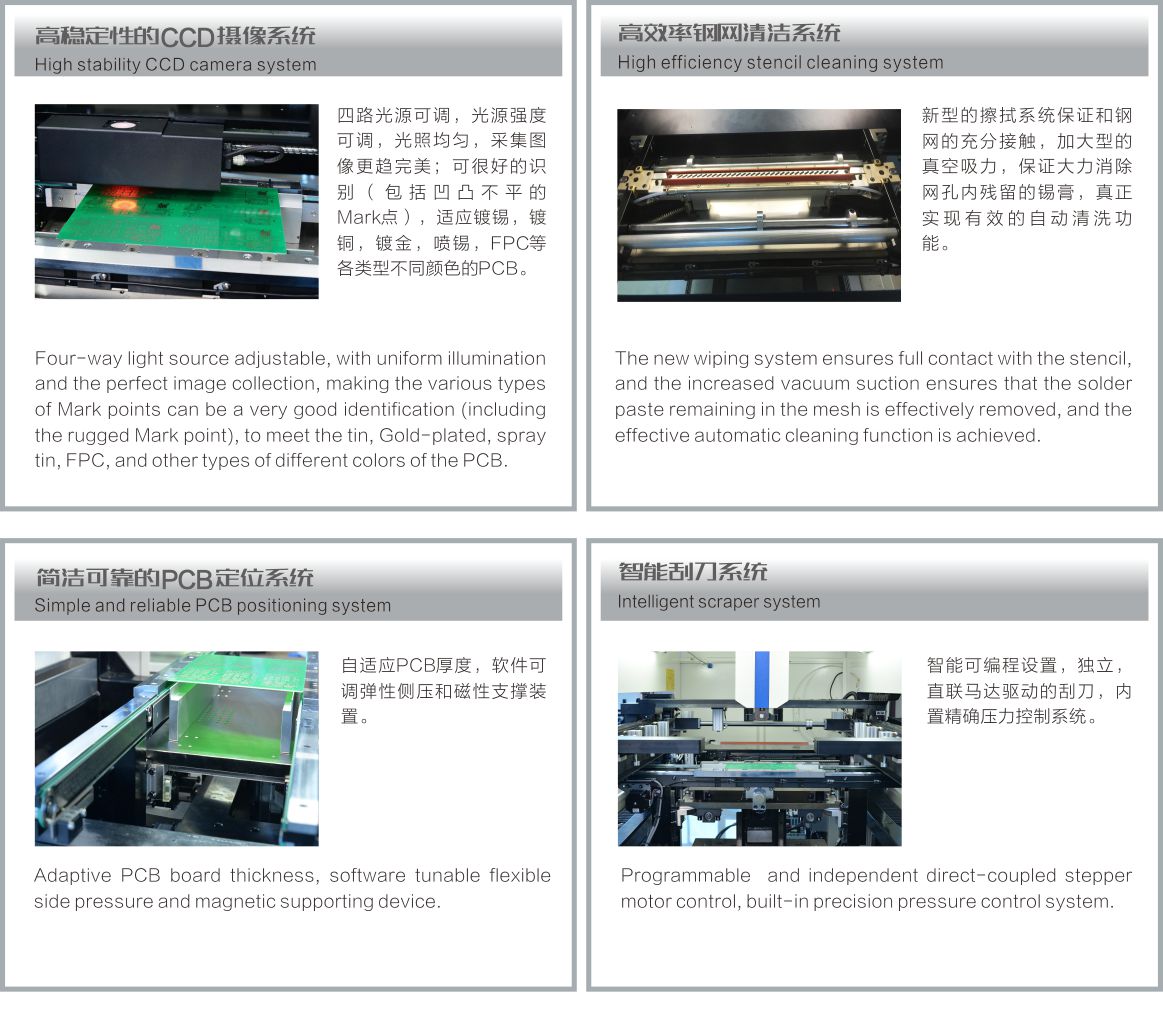

PCB fixing method

Software adjustable pressure elastic side pressure (options: 1, bottom holistic suction vacuum;2, bottom multi-point area vacuum; 3, edge locking substrate clamping)

PCB support Method

Magnetic thimble,equal high block,vacuum suction cavity(option:Grid-Lok)

Printing Parameter

Printing head

Linear motor type close loop printing head

Stencil frame size

370mm x 470mm~737 mm x 737 mm

Max printing area (X x Y)

450mm x 350mm

scraper type

steel scraper/rubber scraper(45°/55°/60)

scraper length

220mm~500mm

scraper height

65±1mm

scraper thickness

0.25mm Diamond-like carbon coating

Printing method

Single or dual scraper

Mould release length

0.02 mm 至 12 mm

Printing

0 ~ 200 mm/s

Printing Pressure

0.5kg -10Kg

Printing length

±250 mm(from center)

Cleaning system

Cleaning method Vacuum Dry Cleaning-Vacuum Wet Cleaning-Dry Cleaning (Programming Control)

Cleaning direction forth-back,Back and forth cleaning (programmed control)

Camera Parameter

Imaging area (FOV)

6.4mm x 4.8mm

Platform adjustment range

X,Y:±7.0mm,θ:±2.0°.

Datum point type

Standard shape reference point (see SMEMA standard), pad/hole

Camera System

Single camera, up/down single imaging vision system, geometric matching positioning

Function Parameter

Repetitive accuracy of image calibration

±10.0um @6 σ,Cp more than 2.0

Printing Repetition Accuracy

±20.0um @6 σ,Cp more than 2.0

Cycle time

Less than 7s

Product changing time

Less than 5 mins

Equipment

Power Supply

AC220V±10%,50/60HZ,15A

Air supply

4~6Kg/cm2, 10.0mm tube

Operation System

Windows XP

Dimension

L(1140mm)x W(1400mm)xH(1480mm)

Weight

1000Kg

Temperature humidity control system(Option)

Temperature Control Range

23±3℃

Humidity Control Range

45~70%RH4

Full Automatic Online SMT solder paste Stencil printer GD450+, Sold big amount in the Market, Good quality is already certificated.

Keywords:

SMT Stencil printer, SMT solder paste printer, SMT printing machine, SMT PCB printer, 600mm Solder paste printer, 1200mm solder paste printer, Solder paste printer, GKG stencil printer, GKG printer.

Contact: Mr Tommy

Phone: +86 13691605420

Tel: +86 -755-85225569

Email: tommy@flason-smt.com

Add: 94#,Guangtian Road,Songgang Street,Bao an District Shenzhen China