Home > SMT Equipment News

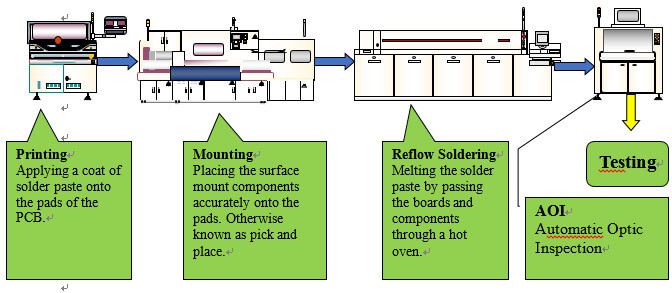

SMT stands for Surface Mount Technology, it's a process for soldering the SMD components to the PCB, the entire technology of mounting and soldering surface mount components onto a printed circuit board or PCB. The actual process is summarised below:

Firstly, a PCB stencil is aligned on the surface of the boards and solder paste is applied using a squeegee to ensure the pads are coated with a uniform and controlled amount of solder paste. Secondly, via a pick and place machine or hand placement, the components are mounted onto the boards in their respective locations. The wet solder paste will act as a temporary adhesive but it is still important to ensure that the boards are moved gently to prevent misalignment. Thirdly, the boards are passed through a reflow oven which subjects the boards to infrared radiation, melting the solder paste and forming solder joints. Then the boards are passed through an AOI machine, or Automatic Optic Inspection machine which runs a number of quality checks on the boards visually, such as component alignment and checking for solder bridges. The boards then proceed to further testing. In the 1980s, SMT production technology became increasingly more refined and as a result, is widely used in mass production. As costs were reduced and technical performance enhanced, more advanced but economical equipment became available. Surface mount technology has numerous advantages, not limited to reducing the volume of devices, such as improved performance, greater functionality and lower costs. As such, SMT brought with it a new generation of electronic assembly technology, which is widely applied in applications from aviation, communications, automotive and medical electronics, down to household appliances and other fields.

SMT equiment including PCB loader, PCB conveyor, Automatic SMT stencil printer or Semi Automatic SMT stencil Printer, Pick and place machine, SMT Reflow Oven, PCB Unloader, AOI machine, SPI machine, and other equipments, all these equipment called SMT assembly line equipment.

PCB loader used to storage many bare PCB or PCB with components on one side, feed the PCB to the SMT stencil Printer and SMT stencil printer print the solder paste on the PCB, then send the pick and place machine, pick and place machine place the components on the PCB then send to reflow oven. Reflow oven solder the components on the PCB, then use AOI inspection the solder quality. SPI used for inspection the solder paste quality that some high end PCB maybe can't repaire or need very few time repaire.

SMD is an abbreviation for surface mount devices, a device assembled using surface mount components and technology. In the early stages, SMD were soldered manually by hand. Then the first batch of pick and place machines could only handle a few simple components. The more complex and smaller components still needed to be placed manually. Not long before the introduction of surface mount components over 20 years ago, a new era was born. From simple resistors to complex ICs, almost every through hole component now has an SMT equivalent.

Keywords:

SMT Assembly line, PCB Assembly line, LED Production line, Automatic SMT Assembly line, Semi Automatic SMT Assembly line, JUKI SMT Assembly Line, Samsung SMT Assembly Line, Hanwha SMT Assembly Line, Panasonic SMT Assembly Line, FUJI SMT Assembly Line, Yamaha SMT Assembly Line.

Contact: Mr Tommy

Phone: +86 13691605420

Tel: +86 -755-85225569

Email: tommy@flason-smt.com

Add: 94#,Guangtian Road,Songgang Street,Bao an District Shenzhen China