Case study: How to Create a Reflow Profile for a 16-layer, 2mm Thickness PCB with a High Density SMT Connector?

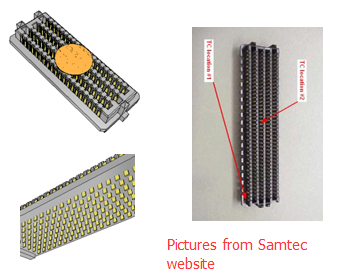

A high density SMT connector, such as the Samtec .050" SEARAY™ High Speed High Density Open Pin Field Array, has up to 500 I/O contact pins with a solder charge termination.

This type of connector looks like a standard BGA type of SMT device. A proper thermal profile for reflow must be evaluated by the process engineer prior to production.

This type of connector looks like a standard BGA type of SMT device. A proper thermal profile for reflow must be evaluated by the process engineer prior to production.

-

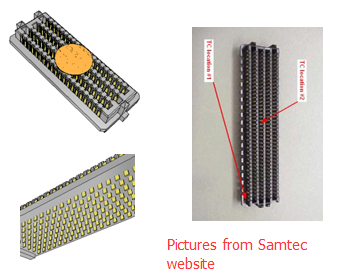

Thermocouple (TC) location

To verify the correct reflow profile, 2~3 thermocouples should be placed beneath the connector: one (1) in the leading corner position, one (1) in the middle of the connector, and one (1) at the trailing corner (optional). These theremocouple placements ensure that all areas of the connector receive even heating sumultaneously.

-

Soak time and TAL consideration

To ensure proper temperature equalization of the whole area beneath the connector, it is recommended that the soak time is long enough as well as the time above liquidus be long enough for a total reflow. Of course, all data must meet with the solder paste manufacturer’s specifications.

-

Preheat and cooling set point

A PCB’s physical properties are also another critical consideration for correct profile adjustment. In this case, the PCB has 16 layers and a 2mm thickness. This mean that this bare board has a high thermal resistance. So, the preheat set point can be adjusted higher than normal; however, the cooling point may lower than normal in order to meet TAL within the specifications.

Here are the testing results in this case study: (Note: this is for reference only):

-

Reflow oven : Concept 7 zone

-

TAL : 60 sec

-

Peak temperature: 245°C

|

Board property

|

Zone 1

|

Zone 2

|

Zone 3

|

Zone 4

|

Zone 5

|

Zone 6

|

Zone 7

|

|

1.6mm, Dual layer, bare PCB

|

110

|

130

|

160

|

180

|

180

|

220

|

250

|

|

2.0mm, Dual layer, bare PCB

|

110

|

135

|

165

|

185

|

185

|

220

|

250

|

|

2.0mm, 16 layer, bare PCB

|

120

|

145

|

180

|

185

|

190

|

230

|

255

|

|

2.0mm, 16 layer, Samtec SEAM connector

|

125

|

150

|

185

|

195

|

195

|

255

|

275

|

Keywords:

SMT Reflow Oven, Lead free Reflow Oven, Reflow Oven Manufacturer, LED reflow oven, PCB Reflow Oven, Nitrogen Reflow Oven, Dual Rail Reflow Oven, China Reflow Oven, wave soldering machine, Dual Rail Wave Soldering Machine, Nitrogen Wave Soldering Machine, Wave Soldering Machine Manufacturer.

Flason Electronic Co.,ltd provide a full SMT assembly line solutions, including

SMT Reflow Oven,

Wave Soldering Machine,

Pick and Place Machine,

SMT Stencil Printer,

SMT AOI SPI Machine,

SMT Reflow Oven,

SMT Peripheral Equipment,

SMT Assembly line,

SMT Spare Parts

etc any kind SMT machines you may need, please contact us for more information:

wechat whatsapp:+8613691605420, Skype: flasonsmt, Email: sales@flason-smt.com |

|

|

|

FAQ

1) This is the first time I use this kind of machine, is it easy to operate?

There is English manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / skype/ phone /trademanager online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

5)Why choose us ?

A. Gold supplier on Alibaba !

B. Trade assurance to US$54,000 !

C. Best price & Best shipping & Best service ! |

|