Which Soldering Defects are Related to the Incorrect Setup of the Reflow Profile?

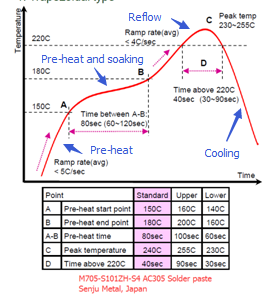

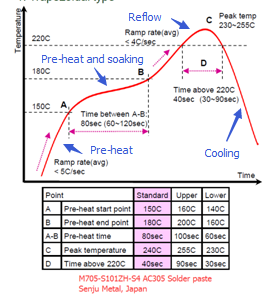

As shown in the figure below, there are four different zones in a typical refow profile – pre-heat, pre-heat and soak, reflow, and cooling zone. The incorrect setup with zone temperatures and times will cause different soldering defects.

-

Pre-heat zone (from room temperature to 150°C)

-

Solder paste collapse -- ramp up too fast

The solvent in flux cannot vapour thoroughly, so the viscosity of the solder paste will be decreased and cause the paste collapse

-

Soldering ball -- ramp up too fast

The solvent in flux vapours out too fast, causing some tiny paste areas to separate from the major paste area and forming individual solder balls around the component.

-

Solder splash – ramp up too fast

Same as soldering ball.

-

Poor wetting – ramp up too slow

Solder paste is oxidizing if the pre-heat too long.

-

Pre-heat and soak zone (from 150°C to 180°C)

-

Tombstone -- ramp up too fast

The PCB and components didn’t get an even heat up.

-

Void -- ramp up too fast

The solvent in flux escaped too quickly.

-

Poor solder joint fillet -- ramp up too slow

The flux lost its activity once it stayed soaking too long.

-

Reflow zone (above 217°C ~220°C for SAC305 solder paste)

-

Component damaged – peak temperature is too high

Once the peak temperature is over 260°C and stays there for more than 10 sec, most of components will be damaged.

-

Cool solder -- peak temperature is too low or time too short

The peak temperature should be 20~25°C higher than the solder liquid point and remains there for 30~90 seconds.

-

Cooling zone (below 217~220°C after reflow)

-

Components crack -- cooling down too fast

Components experienced thermal shock outside of their specifications.

-

Increase component’s fatigue risk –cooling down too slow

Keywords:

SMT Reflow Oven, Lead free Reflow Oven, Reflow Oven Manufacturer, LED reflow oven, PCB Reflow Oven, Nitrogen Reflow Oven, Dual Rail Reflow Oven, China Reflow Oven, wave soldering machine, Dual Rail Wave Soldering Machine, Nitrogen Wave Soldering Machine, Wave Soldering Machine Manufacturer.

Flason Electronic Co.,ltd provide a full SMT assembly line solutions, including

SMT Reflow Oven,

Wave Soldering Machine,

Pick and Place Machine,

SMT Stencil Printer,

SMT AOI SPI Machine,

SMT Reflow Oven,

SMT Peripheral Equipment,

SMT Assembly line,

SMT Spare Parts

etc any kind SMT machines you may need, please contact us for more information:

wechat whatsapp:+8613691605420, Skype: flasonsmt, Email: sales@flason-smt.com |

|

|

|

FAQ

1) This is the first time I use this kind of machine, is it easy to operate?

There is English manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / skype/ phone /trademanager online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

5)Why choose us ?

A. Gold supplier on Alibaba !

B. Trade assurance to US$54,000 !

C. Best price & Best shipping & Best service ! |

|