Home > SMT Assembly News

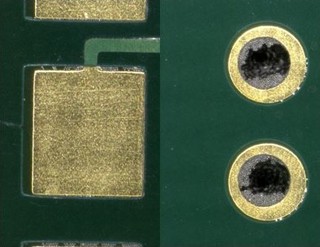

During stencil printing, circuit boards are periodically misprinted due to clogged apertures, stencil out of alignment, solder paste rheology shifts and other issues. Stencil misprints are defined as

The printed circuit board should be cleaned as soon as possible after the mis-print to achieve the best results.

SMT PCB Stencil Cleaning Machine:

Machine Description:

Machine Spec:

Item

SME-800 Spec

Max Stencil Size

L800 x W800 x H40(mm)

Liquid tank

60x2pcs

Clean time

2~5min

Wash time

1~3min,

Dry time

3~5min

Rinse times

1~99time

Clean detergent

Aqueous detergent

Rinse water

DI water(water)open-loop or close-loop

Dry method

High pressure hot air dry

Detergent heat temp

0~60℃

Hot air dry temp

0~90℃

Clean heat power

9KW

Rinse heat power

9KW

Hot air heat power

6KW

Clean/rinse filter

0.45um

Resistivity range

0~18MΩ

Power

AC380V,50/60HZ,28KW

Machine size

L1300xW1400xH1950(mm)

SME-800 is a high quality aqueous detergent stencil cleaning machine which used to clean solder paste stencil, red glue stencil, red glue cooper stencil, mis-print PCB, large size PCBA.

The total process--aqueous detergent clean, water rinse, hot air dry are complete just in one wash chamber. The Unique 4 fixed cleaning spray rods, 4fixed air knives and stencil move back and forth design makes the machine stable, reliable and super cleaning result.

Machine Features:

1.Suitable to clean SMT stencil ,cooper mask, resin mask, misprint PCB and large size PCBA

2.The unique 4 spray rods and 4 air knives fixed and stencil moves clean mechanism, more stable. quick and efficient to clean remaining solder paste ,red glue and flux on SMT stencil ,cooper mask, resin mask, misprint PCB and PCBA.

3.The unique real-time aqueous detergent filtering system is right for precise stencil cleaning.

4.State of the process is visible through a large observation window.

5.Real-time measure DI water resistivity and monitoring cleaning effect.

6.The remaining detergent in the pump and pipes are blown off by compressed air and flow back to cleaning tank. This function saves detergent up to 50%.

7.Can used as PCBA cleaning machine to clean PCBA up to 800mmx800mm

8.English color touch Panel operational interface, PLC procedure control, cleaner temperature, clean time , rinse time and rinse times ,clean temperature, hot air dry time and temperature, resistivity can be set and monitored as required.

Keywords:

SMT Reflow Oven, Lead free Reflow Oven, Reflow Oven Manufacturer, LED reflow oven, PCB Reflow Oven, Nitrogen Reflow Oven, Dual Rail Reflow Oven, China Reflow Oven, wave soldering machine, Dual Rail Wave Soldering Machine, Nitrogen Wave Soldering Machine, Wave Soldering Machine Manufacturer.

Contact: Mr Tommy

Phone: +86 13691605420

Tel: +86 -755-85225569

Email: tommy@flason-smt.com

Add: 94#,Guangtian Road,Songgang Street,Bao an District Shenzhen China