Home > Industry News

Micro LED start up VerLASE announce that it is developing unique technologies for massively parallel assembly of Micro LED dies or films to address the major challenge of Micro LED display mass production.

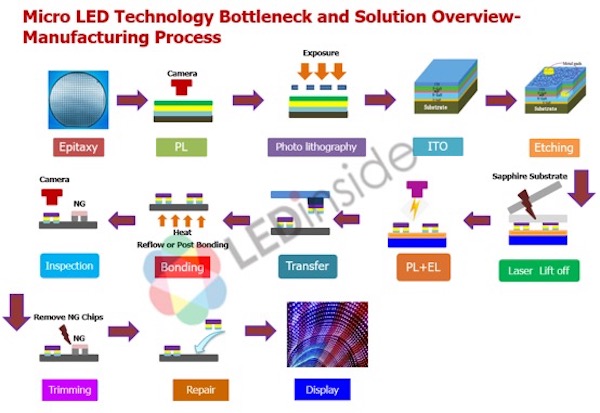

VerLASE, a spin-off of Versatilis, aims to develop novel technology of color conversion layers for Micro LED display. The company focused on practical methods with semiconductor and MEMs industry methods and existing tools in novel ways to enable deterministic, massively parallel transfers of Micro die, yet with provisions that allow selective repair. According to VerLASE, it adopted well developed techniques used daily in Ink-Jet Printing but is not printing per se. Comprehensive patent filings cover multiple variations of the Company’s proprietary core LAAP™ process (Large Area Assembly Process). “In levering the Ink-Jet industry, our solution offers a quick path for Micro LEDs to disrupt the displays industry,” said Ajay Jain, Company CTO and inventor of the technology.

The Company is working on demonstrating the base principles of its solution while in discussions with potential investors. VerLASE had previously focused on Micro LED color conversion technology and related applications and decided to expand its expertise to target the challenge of mass transferring. The company owns seven US Patents covering various aspects in color conversion, including some in Japan, Korea, and China, with others pending. It has now also filed a suite of IP relating to its mass transferring solution.

Keywords:

SMT Reflow Oven, Lead free Reflow Oven, Reflow Oven Manufacturer, LED reflow oven, PCB Reflow Oven, Nitrogen Reflow Oven, Dual Rail Reflow Oven, China Reflow Oven, wave soldering machine, Dual Rail Wave Soldering Machine, Nitrogen Wave Soldering Machine, Wave Soldering Machine Manufacturer.

Contact: Mr Tommy

Phone: +86 13691605420

Tel: +86 -755-85225569

Email: tommy@flason-smt.com

Add: 94#,Guangtian Road,Songgang Street,Bao an District Shenzhen China