Home > SMT Assembly News

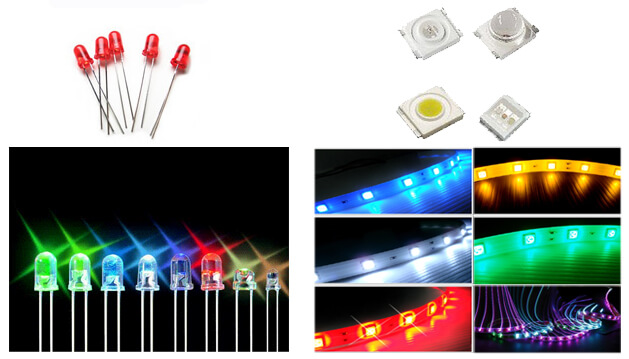

The type of LEDs more commonly used in giant screens are the DIP/PTH LEDs, "Dual Inline-pin Package ","PLATING THROUGH HOLES", or welding through the holes. LEDs are welded on the outside of the printed circuit board, to come into contact with the circuit using the two feet (anode and cathode). With the new SMD LED technology, Surface Mounting Device, or "Surface Mounted Device", the LED is always mounted on the surface of the circuit board, but does not need feet to the link. Another characteristic is their small size, thanks to what you can get 3 different color LEDs within a single LED. " This allows you to display three colors simultaneously with a single LED, this technology allows a smaller distance between the led.

You may ask which is better? This is hard to answer, DIP/PTH and SMD have their own advantages and excellent performance in different areas.

Advantages of DIP/PTH LED:

1. Optimized for moderate to longer viewing distance

2. Louvers deflect sunlight for higher contrast

3. Black matte finish reduces reflection

4. Brighter than SMD LEDs

Advantages of SMD LED:

1. Outstanding color blending at short viewing distance

2. No color shift at extreme angles

3. Wide viewing angle

4. Suitable for automated production

For most LED vehicle lamp manufacturers and factories, SMD is the better choice. The rise and rapid development of Surface Mount Technology, assembly of SMD LEDs does not rely on the human, electronic assembly is becoming more and more fast and simple, the integration is higher and higher, the price is cheaper and more competitive.

PCBA :Printed Circuit Board + Assembly

DIP/PTH: Dual Inline-pin Package/Plating Through Holes

SMD: Surface Mounted Devices

SMT: Surface Mount Technology

ALPCB: Aluminum Printed Circuit Board (aluminum copper clad laminate)

Keywords:

SMT Reflow Oven, Lead free Reflow Oven, Reflow Oven Manufacturer, LED reflow oven, PCB Reflow Oven, Nitrogen Reflow Oven, Dual Rail Reflow Oven, China Reflow Oven, wave soldering machine, Dual Rail Wave Soldering Machine, Nitrogen Wave Soldering Machine, Wave Soldering Machine Manufacturer.

Contact: Mr Tommy

Phone: +86 13691605420

Tel: +86 -755-85225569

Email: tommy@flason-smt.com

Add: 94#,Guangtian Road,Songgang Street,Bao an District Shenzhen China