Home > SMT Assembly News

The purpose of this document is to assist Bittele’s clients in the process generating Gerber files using the software suite known as Eagle. Bittele asks that its clients supply their PCB design files in this format because Gerber is the industry standard file type, and is therefore easily recognized and processed by our manufacturing equipment. We at Bittele recognize that this procedure may not be familiar to all of our clients, and so we will proceed with a step-by-step description in the following section.

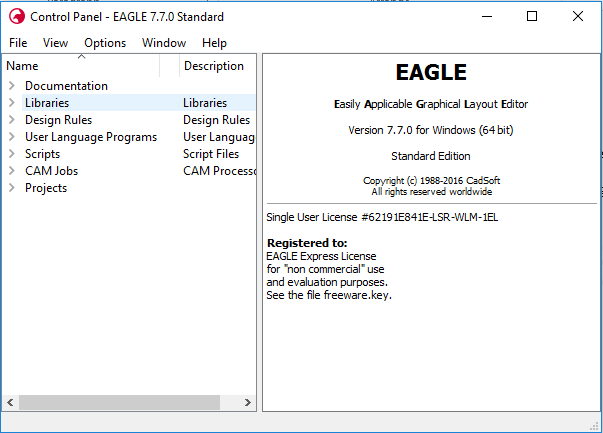

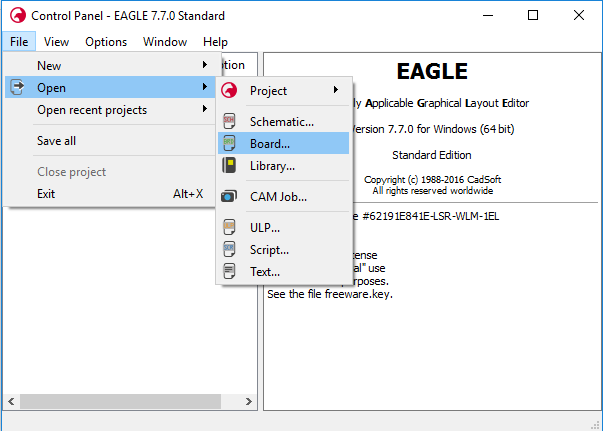

1. Open the control panel for Eagle

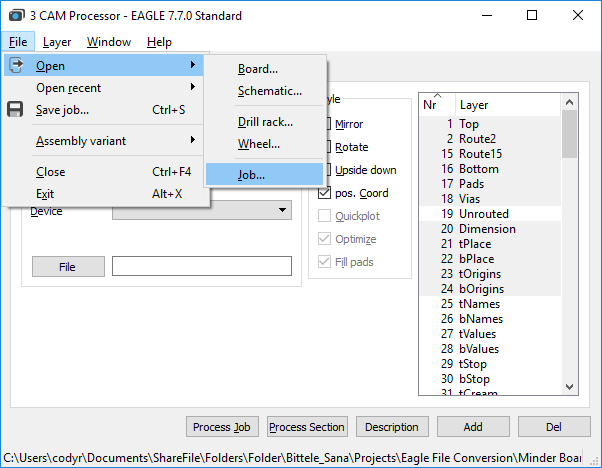

5. A new window will appear for the Cam Processor. In this window, select Open -> Job, as shown:

6. Select gerb274x-mill-drill.cam. This job file is set up for a 2-layer board, but the following examples show how to specify additional layers with the job if you so require.

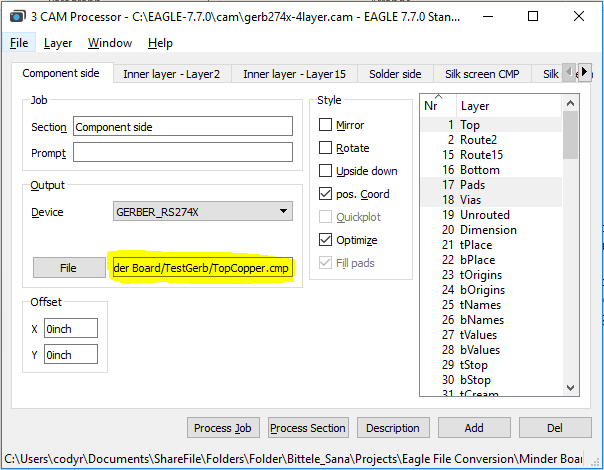

7. In the Output section of the Cam Processor window, select the File button, and navigate to the location in which you would like to store the converted Gerber files. Choose a file name for the layer, for example: the Component Side tab could have the file name “TopCopper.cmp”

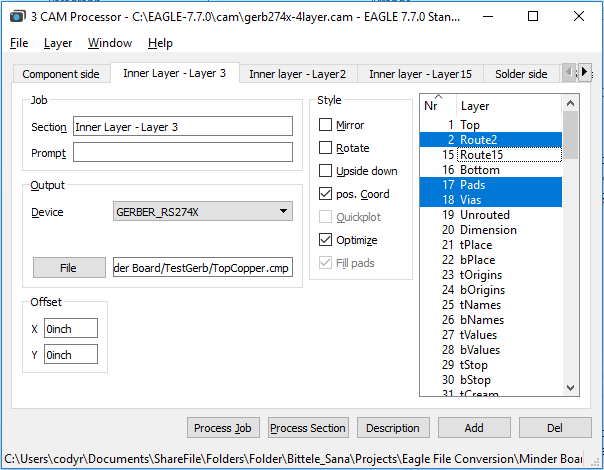

8. If the board is greater than 2 layers, we must use the Add button in the bottom-right corner of the window to duplicate one of the existing copper layers, and modify its settings.

9. Re-name this layer in the Section field of the Job section, then choose the copper layer that it represents from the scrolling list at the far right of the window. For a regular inner copper layer, you should only need to select the copper layer itself (Route2 in above picture), the Pads, and the Vias.

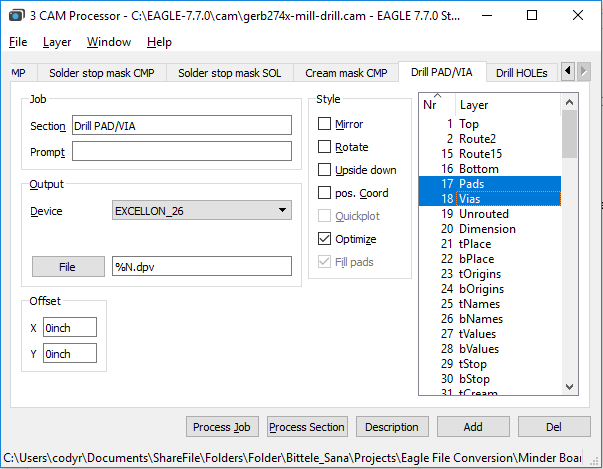

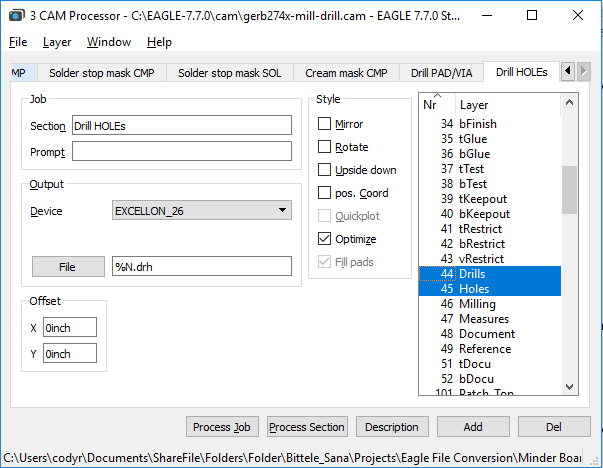

10. Now for the drill files; first choose the tab called “Drill PAD/VIA”, and ensure that the “Pads” layer and the “Vias”layer are selected (these are not selected by default). Also scroll down to ensure that the “Drills” layer is selected, although this one should be selected by default.

11. Next, choose the tab called “Drill HOLEs”, and scroll down in the layers list to ensure that both the “Drills” layer and the “Holes” layer are selected. (Holes is selected by default, but not Drills)

12. Once you have specified File destinations for each of the tabs within the Cam Processor window, select the Process Job button at the bottom of the window.

13. Check the file path that you specified in step 7 to ensure that your Gerber files have been generated successfully. If you have access to a Gerber Viewer software, you can use it now to verify that the contents of your design files were preserved through the conversion procedure.

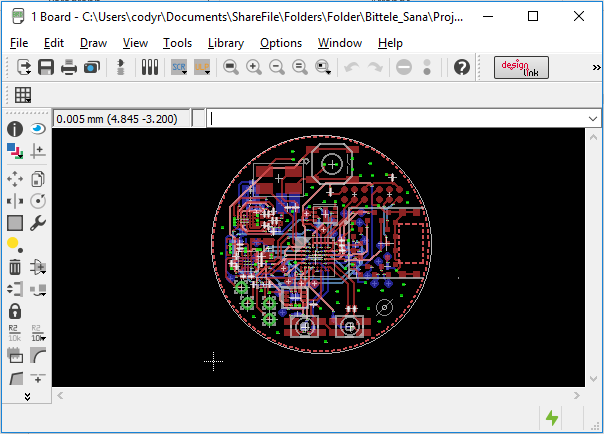

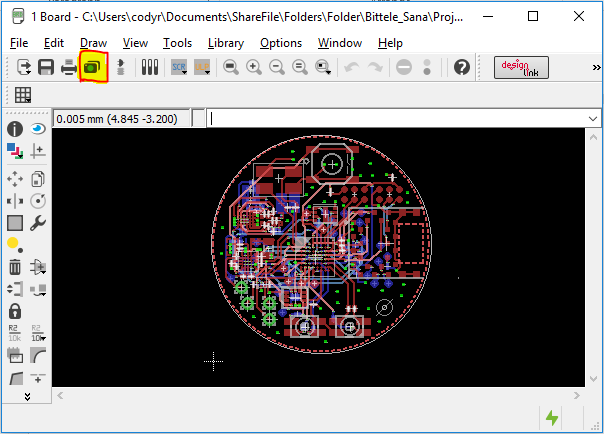

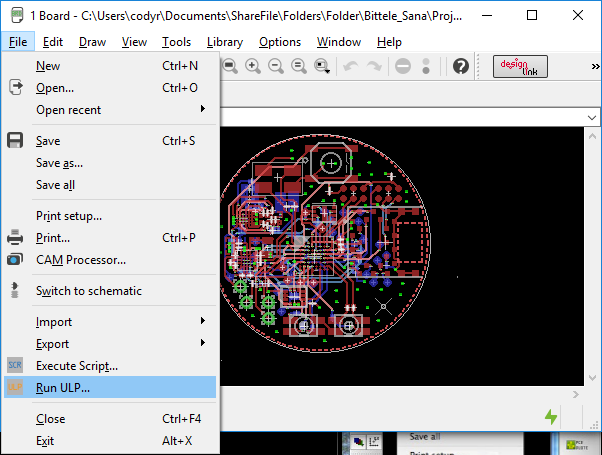

1. From the Board view of your .brd file, select File -> Run ULP

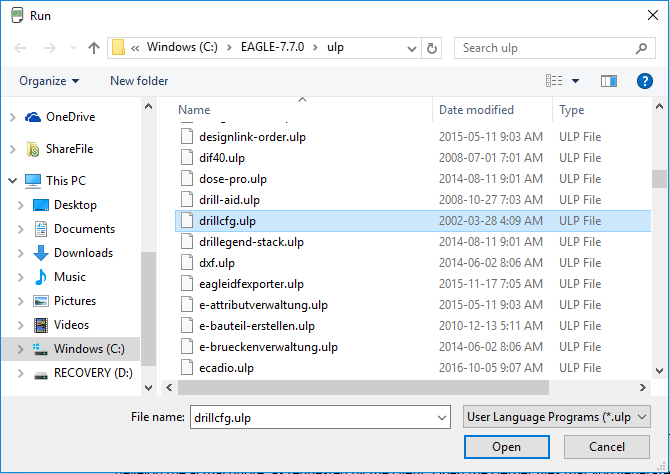

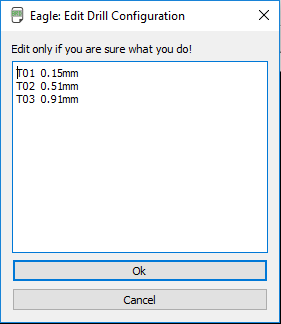

2. Choose the file called drillcfg.ulp

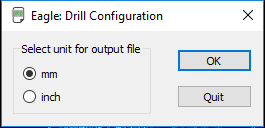

3. Select the measurement units for your drill file. These should match with the measurement units you specified during the design phase for this board. Select Ok.

5. Choose a file location for your drill files, and that’s it, you have successfully exported your Gerber files!

This guide’s aim has been to describe the procedure for generating Gerber files as simply and completely as possible. If you still find yourself unclear on any part of the process, please do not hesitate to contact us:wechat:+86 13691605420 Email:sales@flason-smt.com

Keywords:

SMT Reflow Oven, Lead free Reflow Oven, Reflow Oven Manufacturer, LED reflow oven, PCB Reflow Oven, Nitrogen Reflow Oven, Dual Rail Reflow Oven, China Reflow Oven, wave soldering machine, Dual Rail Wave Soldering Machine, Nitrogen Wave Soldering Machine, Wave Soldering Machine Manufacturer.

Contact: Mr Tommy

Phone: +86 13691605420

Tel: +86 -755-85225569

Email: tommy@flason-smt.com

Add: 94#,Guangtian Road,Songgang Street,Bao an District Shenzhen China