Home > Yamaha Pick and Place Machine

Yamaha YG100 Pick and Place Machine

Products Description:

Yamaha YG100 Pick and Place Machine

Yamaha YG100 Machine's vantage is from 2005 to 2010, mactching windows operating system.

Use single-arm) eight head mount patches, controlled by two motors, easy to maintain and installment,

The price range for used placement machine is abt USD30000-USD50000(Only for reference).

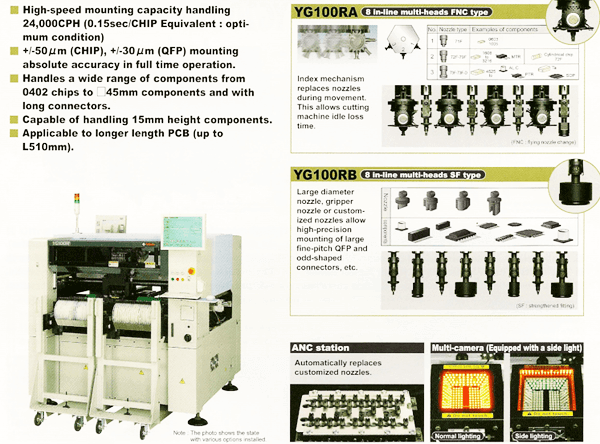

YAMAHA YG100 is a high-performance, high-precision placement machine produced by YAMAHA specifically

for high-speed general purpose machines,it can simultaneously mount different types of special-shaped

components.Using YAMAHA's newly designed head structure,all nozzles up and down control are controlled by

the electric motor, The machine mounting accuracy is greatly improved compared to the previous memory.

YAMAHA YG100 high-speed placement chip, high-precision, high-speed modular placement machine,

high rigidity dual drive structure,High-performance servo system, high-resolution digital multi-vision camera,

multiple precision correction system.

Automatically adjust the transmission width, automatically adjust the height of the mounting surface,

belonging to the YG series classic models.The theory is 25,000 points per hour.

The actual production speed is about 15,000 points per hour.

1. YAMAHA YG100 Placement Machine's advantages:

2. YAMAHA YG100 Placement Machine's parameters:

SMD Components: 0402(MM)-45MMX45MM Components SOP SOJ PLCC QFP BGA

SMD components can be placed 100 kinds (8MM)

Mounter size: L1650XW1562X1470

Yamaha YG100 specification and details as following:

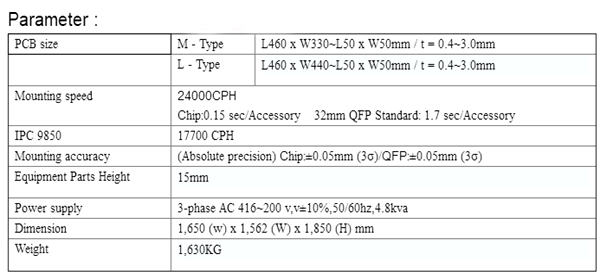

1) Board size: M-Type: L460xW330 ~ L50xW50mm/t = 0.4 ~ 3.0mmL-Type:

L460xW440 ~ L50xW50mm/t = 0.4 ~ 3.0mm * sATS use: L460xW440 ~ L50xW50mm

2) Mounting speed: Chip: 0.15 seconds / accessories / 32mm QFP standard: 1.70 seconds / accessories 3)

IPC9850 conditions: 17700CPH, Chip: 0.20 seconds / accessories

4) Mounting accuracy: Chip: ± 0.05mm (3σ) / QFP: ± 0.05mm (3σ)6) Supported components: 0402 to SOP, SOJ, 84-pin PLCC, 0.5mm pitch QFPBGA,

CSP□31mm, 100mm connector, IC socket.

7) Equipment Parts Height: 15mm8) Part identification methods: multi-angle illumination digital multi-camera system (34 pixels),

multi-angle lighting good vision system (79 pixels).

9) Operation Software: YGOS (FullLine Mode, OnLineHelp, rich accessories and internal organs)10) Optimization Software: Basic Services (Head and Feeder Numbers,

Automatically Specified by the Installer)

11) Remote Control Software: Select (OnLine and OffLine Functions Available13) Safety device: Head collision protection device in two modes: SoftLimit and HardLimit.

The CoverInterlock switch is used for head and collision prevention.

14) Power supply: 3-phase AC 416~200V, V± 10%, 50/60Hz, 4.8kVA0402 (mm series name) - □ 55mm element) SOP/SOJ) QFP) connector) PLCC) CSP/BGA)

long connector (Note 3) (Note 4) (Note 5)

Target component height is 15mm or less (Note 6)L1,650×W1,615 (whole rail end of replacement trolley)×H1,470mm (above cover)

4.YG100RA(FNC type) / YG100RB(SF type)(Model : KHW-000)Absolute accuracy (μ+3σ):+/-0.05mm /CHIP, +/-0.05mm /QFP

Repeatability(3σ):+/-0.03mm /CHIP, +/-0.03mm /QFP

Applicable components

0402(Metric base) to □45mm components, SOP/SOJ, QFP,connector, PLCC, CSP/BGA,

Long connector (Note 3)(Note 4)(Note 5)

Height of components which can be mounted : 15mm or less(Note 6)L1,650xW1,562(End of cover)xH1,470mm(cover top)L1,650xW1,

615(End of guide for feeder carriage)xH1,470mm(cover top)

WeightApprox. 1,630kg(Main unit only)

Keywords:

JUKI RS-1R pick and place machine, JUKI RX-7R pick and place machine, Hanwha SM481 Plus Pick and Place Machine, Hanwha Decan S2 Pick and Place Machine, SMT pick and place machine, JUKI Pick and place Machine, Samsung Pick and Place Machine, Yamaha Pick and Place Machine, Panasonic Pick and Place Machine, FUJI Pick and Place Machine, Siemens Pick and Place Machine.

Contact: Mr Tommy

Phone: +86 13691605420

Tel: +86 -755-85225569

Email: tommy@flason-smt.com

Add: 94#,Guangtian Road,Songgang Street,Bao an District Shenzhen China