Ersa HOTFLOW 3/14 Reflow Oven

Products description

Ersa HOTFLOW 3/14 Reflow Oven

Excellent heat transfer with the most varied board assemblies

Rest-oxygen monitoring with low N2 consumption

Low energy consumption through intelligent energy management

Multi-level controlled cooling

Multi-level process gas cleaning system

"On the fly" maintenance for increased machine availability / uptime

Multi-track conveyor system (1-4)

Ersa Process Control (EPC) for continuous process monitoring

Ersa Auto Profiler software for quickly generating temperature profiles

Ersa HOTFLOW 3/14 Reflow Oven

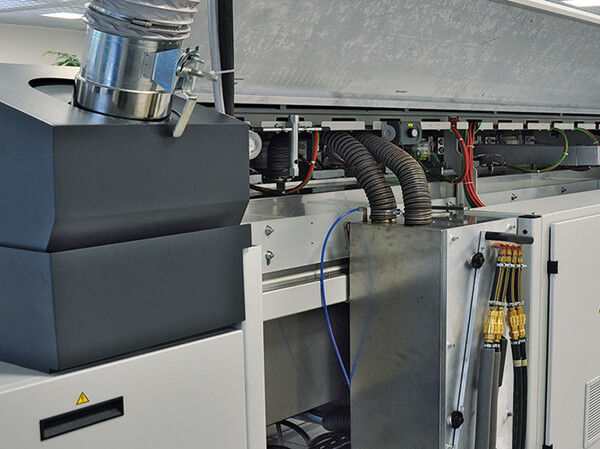

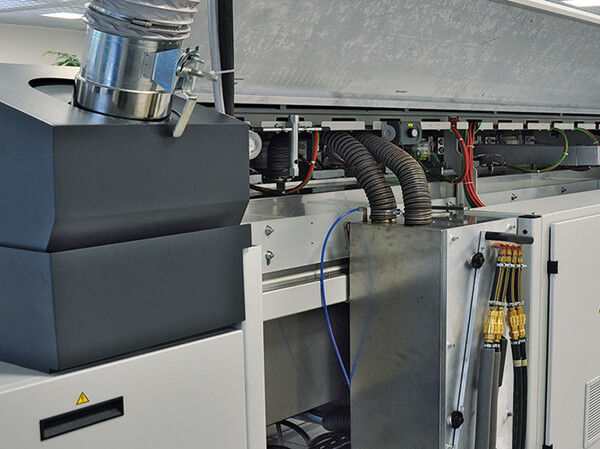

The Ersa HOTFLOW 3/14 reflow system is of robust design and manufactured entirely from steel, welded air-tight, powder coated and with interior electric cabinet and a PC operating terminal. Features include the motorized hood opening, quick-change convection heater cassettes, multi-level process gas cleaning and a powerful and effective cooling zone.

Dimensions

Length: 5,190 mm

Width: 1,530 mm

Height: 1,450 mm

Weight appr. 2,500 kg

Conveyor system

Working width: 45-580 mm automatically infinitely adjustable

Clear passing height: +25 (35)/-37 mm

Centre support, automatically infinitely adjustable

Conveyor speed: 20-200 cm/min

Pin-and-chain conveyor with 3, 4 or 5 mm pins

Process zone

Process length: 3,790 mm

Heated length: 2,650 mm

Cooling length: 1,140 mm

Heating system

Up to 14 convections heating cassettes

(Preheat zone up to 10 cassettes, reflow zone up to 4 cassettes)

Volumetric flow rate each module, adjustable up to 500 m3/h

Rated power each module: 3.3 kW

Cooling

Up to 3 level cooling zone with water back cooling

Electrical data

400 V, 3 Phase, N, Ground, 50/60 Hz

Continuous output during operation: appr. 9-15 kW

Exhaust

Extraction capacity 2 stacks each 400 m3/h, monitored

Options:

Multi-track conveyor system with separate drives each track

Connectable center supports

Inert atmosphere feature, available with rest-oxygen monitoring and control

Metering of N2 consumption

Power-cooling with 3 convection modules and "on the fly" process gas cleaning

Emergency power supply

Ersa Process Control (EPC)

Auto Profiler

Energy consumption computation

Quick profile change

Keywords:

SMT Reflow Oven, Nitrogen Reflow Oven, Dual Lane Reflow Oven, Vertical Reflow Oven, Vacuum SMT Reflow Oven, Lead free SMT Reflow Oven, Reflow Oven Manufacturer, LED Reflow Oven, China Reflow Oven.

Flason Electronic Co.,ltd provide a full SMT assembly line solutions, including

SMT Reflow Oven,

Wave Soldering Machine,

Pick and Place Machine,

SMT Stencil Printer,

SMT AOI SPI Machine,

SMT Reflow Oven,

SMT Peripheral Equipment,

SMT Assembly line,

SMT Spare Parts

etc any kind SMT machines you may need, please contact us for more information:

wechat whatsapp:+8613691605420, Skype: flasonsmt, Email: tommy@flason-smt.com |

|

|

|

FAQ

1) This is the first time I use this kind of machine, is it easy to operate?

There is English manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / skype/ phone /trademanager online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

5)Why choose us ?

A. Gold supplier on Alibaba !

B. Trade assurance to US$54,000 !

C. Best price & Best shipping & Best service ! |

|