Home > SMT Assembly Line

PCBA Assembly Line

Specifications:

Flason Electronic Co., Ltd. : To provide professional SMT automatic production line solution, The company specializes in SMT chip mounter(New Samsung: SM482, SM481, SM471, Decan-F2 etc); YAMAHA SMT machine (YAMAHA Chip shooter); JUKI chip mounter, Siemens SMT machine, Panasonic SMT Chip mounter, FUJI second-hand SMT machine. We are also sell printing machine, Point glue machine, Reflow soldering, Wave soldering, Automatic plug-in machines, stencil printer, Reflow oven, flow welding, AOI, X-ray, LED automatic die bonder etc, For communication products manufacturers, LED display, lighting manufacturers; SMT, AI materials processing, and other enterprises provide the required equipment or wiring scheme.

SMT MACHINE,PCBA production line (SMT printer+SMT pick and place machine+reflow oven)

Main new

Samsung chip mounter: SM482,SM471, SM481, Decan-F2 etc.

YAMAHA SMT machine: YS12, YS24, YS12F, YG12, YG100RA, YV100X,YS24F

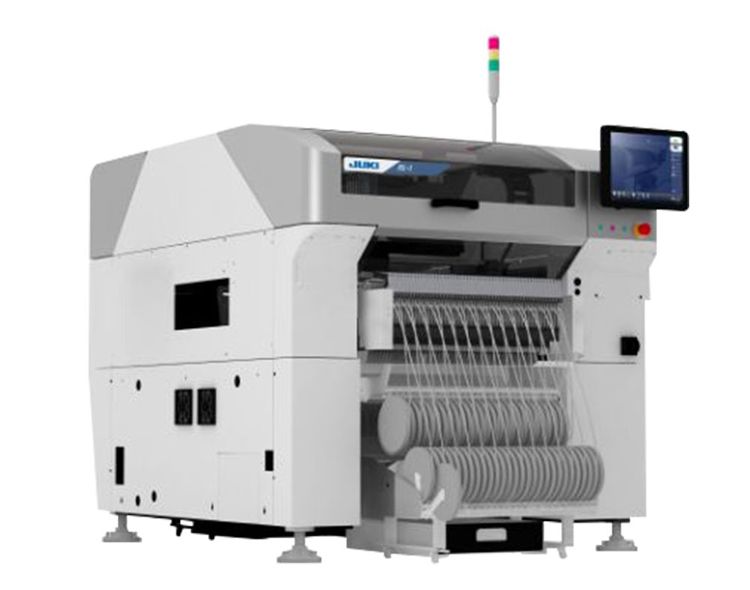

JUKI Chip shooter: FX-3PAL, KE-3010, KE-3020, JX-350LED

SMT WORKSHOP LINE,LED production line (SMT LOADER+SMT printer+SMT SPI+SMT pick and place machine+reflow oven)

SMT Assembly Line(SMT printer+SMT pick and place machine+reflow oven

NEW automatic plug-in machines, horizontal plug, Vertical plug, Bulk LED plug, Reflow oven, wave soldering, domestic, import have lead, lead-free reflow soldering; Wave soldering,

Other SMT related equipment: : AOI; X - ray testing equipment t; Semi-automatic and fully automatic printing machine.

1. Semi auto solder paste paster

a) Support wide spectrums of PCB size from 50mm x 50mm to 1200mm x 340mm and PCB thickness from 0.6mm to 6mm.

2.PCB Conveyor

Function: Transport PCBs Specification: length: 0.5-2.0m SMEMA avoilable

3.Pick and place machine

1) World-leading productivity with the ultra-high-speed rotary head

New development of the ultra-high-speed RS head which is capable of pickup in half the time of conventional rotary heads is achieved due to its industry-first revolutionary simultaneous pickup mechanism.

2) High precision, high quality mounting for miniature chips

The stronger suction achieved via a high-performance vacuum pump allow more stable and reliable pickup performance. Newly-developed Juki Motor-exclusive high-speed side-view cameras check the status of components in real time without loss immediately after pickup and then before and after mounting. The machine to handle 0201-sized miniature chip components and achieve high reliability and high-quality mounting.

3) Long term reliability and easy maintenance

The Pick and Place Machine head is fitted with a filter at the tip of the shaft to help prevent the inside of the head from becoming dirty. Standard provision of a Blow Station enables automatic self-cleaning of the nozzle shaft, reducing the amount of maintenance work required.Additionally, machine stop loss is significantly reduced by the automatic prevention of pickup and recognition errors due to - such as e-Vision, the component data auto generating and tracking system, Smart Recognition, which easily produces complex shaped component data, and Pickup-MACS, an automatic correction system of pickup position.

4) One platform, wide flexibility

Capable of working flexibly in a wide range of production formats thanks to (1) the two-typed two-beam layout that can operate with odd-shaped chips as well as the four-beam layout suitable for ultra-high-speed production, (2)the dual lane layout conveyor device able to achieve a wide range of variations.

4.Reflow oven

Function: PCB welding. Strengths: save a lot of labor cost!

According to the special requirement, we can chose the best suitable for customers.

such as add computer, rail ect.

1. The brand computer and Siemens PLC intelligent control system, high precision temperature control is ± 1-2 ? (if the computer crash accident, it can realize off-line work, do not affect production) and to ensure that the control system is stable and reliable;

2. Windows XP operating interface with powerful and simple operation.

3.In order to ensure safety and reliability, the cylinder body can be lift up automatically.

4. Device is equipped with mesh belt, transport smoothly, no shaking and no deformation, which ensure smooth PCB transport. Synchronous guide transmission mechanism and automatic SMT machine online connection ensure that guide adjustable wide precision and high service life.

5. Automatic control lubrication system and automatic lubrication transmission chain.

6.All heating zone control by computer PID(upper temperature zone and lower temperature zone implementation independent temperature control, that means it can divide temperature area heat, in order to reduce starting power)

7. Net/chain transmission by computer to carry out the whole closed loop control, which can meet different kinds of PCB production at the same time.

8. With fault sound and light alarm function.

9. With leakage protector, ensure that the operating personnel and control system security.

10.The built-in UPS and automatic delay shutdown system guarantee return welder in power or overheat do not damaged PCB and the machine.

Keywords:

SMT Assembly line, PCB Assembly line, LED Production line, Automatic SMT Assembly line, Semi Automatic SMT Assembly line, JUKI SMT Assembly Line, Samsung SMT Assembly Line, Hanwha SMT Assembly Line, Panasonic SMT Assembly Line, FUJI SMT Assembly Line, Yamaha SMT Assembly Line.

Flason Electronic Co.,ltd provide a full SMT assembly line solutions, including SMT Reflow Oven, Wave Soldering Machine, Pick and Place Machine, SMT Stencil Printer, SMT AOI SPI Machine, SMT Reflow Oven, SMT Peripheral Equipment, SMT Assembly line, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: wechat whatsapp:+8613691605420, Skype: flasonsmt, Email: tommy@flason-smt.com

Contact: Mr Tommy

Phone: +86 13691605420

Tel: +86 -755-85225569

Email: tommy@flason-smt.com

Add: 94#,Guangtian Road,Songgang Street,Bao an District Shenzhen China