Home > Industry News

If you are in Electronics Industry, Electronics Assembly and Manufacturing or Electronics Rework / repairing then you must have heard of RoHS, WEEE and Lead-Free.

Let us discuss these in detail:

What is RoHS?

RoHS stands for Restriction of Hazardous Substances. RoHS, also known as Directive 2002/95/EC, originated in the European Union and restricts the use of specific hazardous materials found in electrical and electronic products. All applicable products in the EU market after July 1, 2006 must pass RoHS compliance.

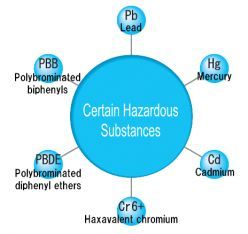

What are the Restricted Materials Mandated Under RoHS?

RoHS Logo

The substances banned under RoHS are lead (Pb), mercury (Hg), cadmium (Cd), hexavalent chromium (CrVI), polybrominated biphenyls (PBB) and polybrominated diphenyl ethers (PBDE).

Why is RoHS compliance important?

The restricted materials are hazardous to the environment and pollute landfills, and are dangerous in terms of occupational exposure during manufacturing and recycling.

How are products tested for RoHS compliance?

Portable RoHS analyzers, also known as X-ray fluorescence or XRF metal analyzers are used for screening and verification of RoHS compliance. Other Products are also available to check presence of Hazardous Substances.

Which companies are affected by the RoHS Directive?

RoHS Substances

Any business that sells applicable electronic products, sub-assemblies or components directly to EU countries, or sells to resellers, distributors or integrators that in turn sell products to EU countries, is impacted if they utilize any of the restricted materials.

What is WEEE?

WEEE stands for Waste from Electrical and Electronic Equipment. WEEE, also known as Directive 2002/96/EC, mandates the treatment, recovery and recycling of electric and electronic equipment. All applicable products in the EU market after August 13, 2006 must pass WEEE compliance and carry the “Wheelie Bin” sticker.

How are RoHS and WEEE related?

WEEE

WEEE compliance aims to encourage the design of electronic products with environmentally-safe recycling and recovery in mind. RoHS compliance dovetails into WEEE by reducing the amount of hazardous chemicals used in electronic manufacture.

What is Lead-Free?

Solder Wire with NO LEAD (Pb) is called Lead-Free or Lead-Free Solder.

Lead-Free Soldering – Why?

WEEE Recycle Chart

The simplest explanation for the tremendous interest in lead-free soldering is FEAR: Fear of Legislation, Fear of Trade Barriers, and Fear of Competition. Most companies do not necessarily want to change to lead-free, but rather are motivated by a combination of these three fears.

The WEEE / RoHS directives in Europe and similar mandates in Japan have instilled fear that a legislative body will prohibit the use of lead in electronics soldering.

If a particular country disallows lead in electronics, a trade barrier is created between that country and anyone not capable of providing lead-free electronics solutions. Of course, this also could take place between individual companies.

Some companies already are producing electronics products with lead-free solder alloys and marketing them as such. This has led to fears of being caught behind commercially.

Frequently Asked Questions (FAQ) On Lead-Free Soldering

Why is there a push for lead-free solders in electronics soldering applications?

Lead-Free Logo

The health and liability risks associated with the use of lead have led to government regulations concerning the elimination of lead from certain manufacturing processes. Lead already has been banned from paint, plumbing, and gasoline. Solder is likely to be regulated in the near future as well.

Why should some lead-free alloys be approached cautiously?

The compositions and traits of lead-free solder alloys vary greatly. However, some alloys should be approached cautiously:

Are lead-free alloys as durable as tin-lead alloys?

Many of the available lead-free alloys offer significant durability advantages over tin-lead alloys. Benefits such as higher joint strength, better fatigue resistance, improved high temperature life, and harder solder joints are common to some of these alloys. However, these benefits vary greatly among the various lead-free alloys, and research is required in order to choose the correct alloy.

How do lead-free alloys compare to tin-lead alloys for application temperature requirements?

Typically, lead-free alloys have higher melting points than tin-lead alloys. These range from 215°C to 240°C. It is very important to consider the melting point while choosing a lead-free alloy, as many components and materials cannot withstand the very high reflow peak temperatures (upwards of 260°C) of some tin-silver and tin-copper alloys.

Are lead-free alloys compatible with all flux types?

In general, lead-free alloys may be used with most flux chemistry. Again, however, these alloys vary greatly, and compatibility with solder paste, cored wire solder, and liquid flux chemistry is dependent upon the melting point and composition of the alloy.

In what solder forms can lead-free alloys be produced?

Most lead-free alloys are available in all solder forms, including solder paste, cored wire solder, solid wire, bar solder, spheres and preforms. Exceptions to this are alloys that contain a high amount of indium or bismuth, which cannot be produced as cored wire solder due to manufacturing issues.

What are the attributes that one should look for while searching for a lead-free solder alloy?

Lead-free solder alloys should possess the following characteristics:

Are lead-free alloys compatible with no clean flux chemistry?

Many users of fluxes and solder pastes have (justifiably) wondered if they will have to switch chemistry when they switch to a lead-free process. The answer is: It depends. If you switch to a high melting point alloy such as tin-silver or tin-copper, then it is likely that a change will have to be made. However, with lower melting point lead-free alloys (If there exists any) it is much more likely that you can continue to use the same flux chemistry without resulting in charred residues, dewetting, cleaning difficulties, etc. Of course, this is most dependent upon the thermal stability of the flux chemistry being used.

Lead-Free Alloy Element Tolerances

Solder alloys have an acceptable tolerance for each component element in the alloy. Per IPC-J-STD-006, elements that constitute up to 5% of an alloy may vary by up to ±0.2%, while elements that constitute greater than 5% of an alloy may vary by up to ±0.5%.

For example, the Sn63/Pb37 alloy may contain between 62.5% to 63.5% tin and 36.5% to 37.5% lead. The Sn62/Pb36/Ag2 alloy may contain between 61.5% to 62.5% tin, 35.5% to 36.5% lead and 1.8% to 2.2% silver.

Below is a chart of various lead-free alloy compositions and their potential elemental range.

Lead-Free Alloy Element Tolerances

Keywords:

SMT Reflow Oven, Lead free Reflow Oven, Reflow Oven Manufacturer, LED reflow oven, PCB Reflow Oven, Nitrogen Reflow Oven, Dual Rail Reflow Oven, China Reflow Oven, wave soldering machine, Dual Rail Wave Soldering Machine, Nitrogen Wave Soldering Machine, Wave Soldering Machine Manufacturer.

Flason Electronic Co.,ltd provide a full SMT assembly line solutions, including SMT Reflow Oven, Wave Soldering Machine, Pick and Place Machine, SMT Stencil Printer, SMT AOI SPI Machine, SMT Reflow Oven, SMT Peripheral Equipment, SMT Assembly line, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: wechat whatsapp:+8613691605420, Skype: flasonsmt, Email: sales@flason-smt.com

Contact: Mr Tommy

Phone: +86 13691605420

Tel: +86 -755-85225569

Email: tommy@flason-smt.com

Add: 94#,Guangtian Road,Songgang Street,Bao an District Shenzhen China